| |

Products >

Auto-Capsule Filling Machine |

| |

Auto-Capsule Filling Machine |

| |

|

| |

Benefits: Benefits: |

| |

|

- Transparent gate for easy empty the capsule hopper

- Movable touch screen with PLC control

- Easy screw shaft adjustment for different size capsule perfect joint

- Air purge nozzles insert into the mold with vacuum suction for dedusting

- Auto-tension adjustment of driven chain among the main motor and the indexes

- Movable caster design for flexible product line layout

- One piece rigid capsule hopper

- Auto solenoid valve control capsule reject instead of conventional manual cock valve

- Dust-proof ventilation filter

- Above-mentioned multi-national patents

|

| |

|

| |

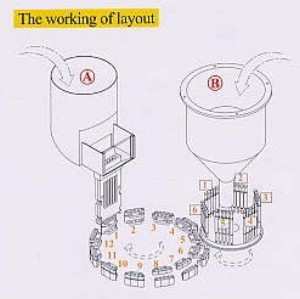

The Empty capsule storage hoppers The Empty capsule storage hoppers |

| |

|

- Empty capsule loading

- Capsule separating

- Upward and backward movement of cap segment

- Powder filling

- Granule or tablet

- Ejection of faulty capsules

- Forward and downward movement of cap segment

- Capsule closing

- Ejection of capsules

- Air purge / vacuum cleaning

|

| |

|

| |

The Powder storage hopper The Powder storage hopper |

| |

|

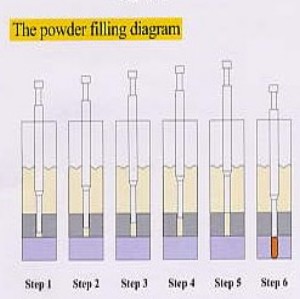

The accuracy tamping process

To achieve a high content uniformity of the filled Capsules, the following powder tamping process is adopted. Powder is auger-fed from a storage hopper to the filling chamber, which completely surround a filling disc is performed intermittently at five successive stations. Each tamp will gradually increase powder weight in the holes. At the 6th station, the tamp rod pushed powder into the capsule body. With the powder height in the filling chamber level-controlled and the tamping depth externally adjustable at each individual tamping station the fill accuracy is guaranteed at the highest possible level. |

| |

|

| |

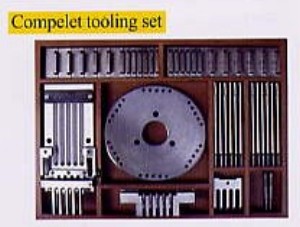

Size Change Part: Size Change Part: |

| |

|

It requires changing the dosing disc, tamping pins, capsule feeder, orientation parts and capsule segments disassembly and reassembly is very easy. |

| |

|

| |

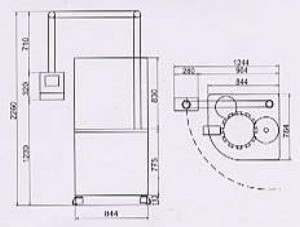

Technical Data: Technical Data: |

| |

|

| Output apsules / hour |

Max. 40,000 |

| Standard capsule size |

00#, 0#, 1#, 2#, 3#, 4#, 5# |

| Power consumption |

3HP |

| Dimension (WxDxH) |

764 x 1,244 x 2,260 mm (Approx) |

| Net Weight |

900 kgs (Approx) |

|

| |

|

|

| |

|